Mejora de la excavación de túneles: el papel fundamental de la tecnología de sistemas de voladura de rocas con CO₂

El sistema produce emisiones más limpias, principalmente vapor de agua y dióxido de carbono, que son menos nocivos que los gases tóxicos de los explosivos. Además, la intensidad reducida de las ondas de choque minimiza la vibración del suelo y la contaminación acústica, preservando el medio ambiente circundante y reduciendo las perturbaciones ecológicas.

A3:

Si bien el sistema de CO₂ ofrece numerosas ventajas, se deben abordar desafíos como la necesidad de equipos especializados, los costos iniciales de instalación y la gestión del suministro de CO₂ líquido. Sin embargo, los avances tecnológicos continuos están mitigando continuamente estas limitaciones, lo que hace que los sistemas de CO₂ sean cada vez más viables para su adopción generalizada.

Perspectiva dialéctica: equilibrio entre beneficios y desafíos¿Está la tecnología del sistema de voladura de rocas con CO₂ preparada para reemplazar por completo los explosivos tradicionales en la excavación de túneles?

Si bien los sistemas de CO₂ ofrecen importantes beneficios ambientales y de seguridad, los explosivos tradicionales siguen prevaleciendo debido a su eficacia establecida y menores costos iniciales. Sin embargo, a medida que las industrias priorizan cada vez más las prácticas sostenibles y más seguras, se espera que la adopción de voladuras de rocas con CO₂ aumente, en particular en regiones con estrictas regulaciones ambientales y de seguridad. Con el tiempo, los avances tecnológicos y las economías de escala pueden mejorar aún más la viabilidad de los sistemas de CO₂, lo que potencialmente conducirá a una adopción más amplia y al reemplazo final de los explosivos tradicionales en ciertas aplicaciones.¿Pueden los sistemas de voladura de rocas con CO₂ igualar la producción de energía de los explosivos tradicionales?

Sí, los sistemas de CO₂ están diseñados para proporcionar salidas de energía comparables, si no superiores, para la fragmentación de rocas. La rápida expansión del CO₂ líquido genera ondas de choque de alta presión capaces de romper de manera efectiva formaciones de roca dura. Además, la naturaleza controlable de estos sistemas permite una gestión precisa de la energía, lo que garantiza que el proceso de voladura sea eficiente y seguro.Perspectivas futuras

El futuro de la excavación de túneles depende de la innovación y la adopción continuas de tecnologías de voladura alternativas, como el sistema de voladura de rocas con CO₂. A medida que las industrias de la minería y la construcción reconocen cada vez más la importancia de la seguridad y el cuidado del medio ambiente, se espera que la demanda de dichas tecnologías aumente. Las inversiones en investigación y desarrollo mejorarán aún más la eficiencia, la fiabilidad y la asequibilidad de los sistemas de CO₂, haciéndolos aún más atractivos para una gama más amplia de aplicaciones.Adopción del mercado:

A medida que las industrias de todo el mundo se esfuerzan por cumplir con las estrictas normas ambientales y de seguridad, es probable que se acelere la adopción de sistemas de voladura de rocas con CO₂. Los primeros en adoptarlos en países con marcos regulatorios sólidos allanarán el camino para una aceptación global más amplia, estableciendo puntos de referencia para la seguridad y el desempeño ambiental.Soporte regulatorio:

Los gobiernos y los organismos reguladores apoyan cada vez más las tecnologías que reducen el impacto ambiental y mejoran la seguridad de los trabajadores. Las políticas que fomentan la adopción de métodos de voladura más limpios y seguros facilitarán la implementación generalizada de sistemas de voladura de rocas con CO₂ en la construcción de túneles y otras aplicaciones.

Traditional Explosive Methods in Tunnel Excavation

Explosive rock blasting has been the go-to method for tunnel excavation due to its high energy output, cost-effectiveness, and ability to break through hard rock swiftly. The process involves:

Drilling Holes: Precise holes are drilled into the rock face using drilling machines.

Loading Explosives: Explosive charges, often ammonium nitrate-based, are placed into the drilled holes.

Detonation: The explosives are detonated in a controlled sequence to fracture the rock.

Technical Highlights of Traditional Explosives:

High Energy Output: Capable of generating substantial force to break through dense rock formations.

Adjustable Power: The energy release can be modified by altering the explosive composition and quantity.

Cost-Effective: Generally, explosives are less expensive compared to alternative rock-breaking technologies.

Challenges with Traditional Explosives

Despite their effectiveness, traditional explosives pose several significant challenges, especially in tunnel excavation:

Safety Risks:

Accidental Detonations: The handling and transportation of explosives carry inherent risks of accidental explosions.

Flyrock: Uncontrolled projectiles can endanger workers and nearby structures.

Intense Shockwaves: The powerful shockwaves can cause structural damage to tunnel supports and pose health risks to personnel.

Environmental Impact:

Toxic Gas Emissions: Explosive detonations release harmful gases like nitrogen oxides and carbon monoxide, contributing to air pollution.

Noise and Vibration: The blasting process generates significant noise and ground vibrations, disrupting surrounding environments and potentially causing geological instabilities.

Operational Limitations:

Permit Requirements: The use of explosives is heavily regulated, requiring stringent permits that can delay project timelines.

Restricted Use Areas: Proximity to residential zones or sensitive ecosystems often limits where explosives can be safely employed.

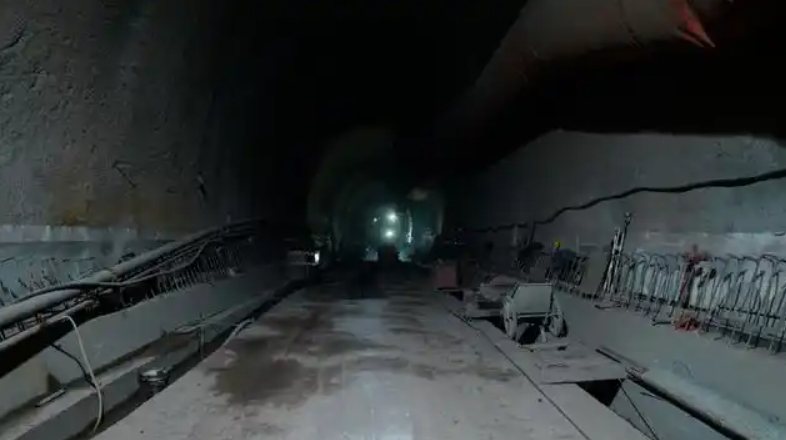

Introducing CO₂ Rock Blasting System Technology

To address the shortcomings of traditional explosives, the CO₂ Rock Blasting System Technology has emerged as a safer, more controllable, and environmentally friendly alternative. This innovative system leverages the physical expansion of liquid carbon dioxide (CO₂) to generate high-pressure shockwaves for rock fragmentation.

How Does CO₂ Rock Blasting Work?

Preparation:

Site Assessment: Similar to traditional methods, a professional engineer assesses the tunnel site to design an optimal drilling plan.

Drilling Holes: Holes with diameters ranging from 40mm to 127mm are drilled to specified depths, typically between 1.2m and 5.15m, depending on geological conditions.

Loading the System:

Rock Splitting Tubes: CO₂ rock blasting tubes, filled with heating elements and connected to gas filling tanks, are inserted into the drilled holes.

Gas Injection: Liquid CO₂ is introduced into the tubes via specialized gas connect pipes until the desired pressure is achieved.

Activation:

Remote Control: The blasting process is initiated remotely using a controller, triggering the heating elements.

Phase Transition: The liquid CO₂ rapidly transitions to gas, expanding approximately 600 times its original volume and generating a powerful shockwave that fractures the surrounding rock.

Post-Blasting:

Safety Measures: Soil is refilled around each hole to prevent flyrock, and personnel are safely evacuated from the vicinity before activation.

Advantages of CO₂ Rock Blasting in Tunnel Excavation

1. Enhanced Safety:

Controlled Energy Release: The CO₂ system produces shockwaves that are significantly less intense (about 70% lower) than traditional explosives, minimizing the risk of flyrock and structural damage.

Non-Flammable Components: CO₂ is an inert gas, eliminating the risk of accidental fires or explosions, making it ideal for use in environments with combustible gases.

2. Environmental Friendliness:

Clean Emissions: The primary byproducts are water vapor and carbon dioxide, which are less harmful compared to the toxic gases from explosives.

Reduced Vibration and Noise: The lower intensity of shockwaves translates to minimal ground vibration and noise pollution, preserving the surrounding environment and reducing disturbances to nearby ecosystems.

3. Operational Efficiency:

Versatility in Harsh Conditions: CO₂ systems are effective in high-temperature and water-filled drilling holes, conditions where traditional explosives may fail or require additional safety measures.

Cost-Effective Demolition: With an approximate cost of $1 per cubic meter, CO₂ rock blasting is competitively priced, especially when considering its durability and efficient usage of CO₂.

4. Precision and Control:

Adjustable Parameters: The system allows for precise control over the blasting process, enabling adjustments to the CO₂ and fuel mixture to suit specific geological conditions and desired fragmentation levels.

Consistent Rock Fragmentation: Ensures high-quality, uniform rock fragmentation, facilitating easier and more efficient muck removal and tunnel lining installation.

Addressing Common Questions

Q1: How does the CO₂ Rock Blasting System compare to traditional explosives in terms of safety?

A1: The CO₂ Rock Blasting System significantly enhances safety by eliminating the risks associated with explosive detonations. The controlled energy release reduces the likelihood of flyrock and structural damage, while the use of inert CO₂ prevents accidental fires and explosions, making it ideal for use in environments with combustible gases.

Q2: What are the environmental benefits of using the CO₂ Rock Blasting System?

A2: The system produces cleaner emissions, primarily water vapor and carbon dioxide, which are less harmful than the toxic gases from explosives. Additionally, the reduced shockwave intensity minimizes ground vibration and noise pollution, preserving the surrounding environment and reducing ecological disturbances.

Q3: Are there any limitations to the adoption of the CO₂ Rock Blasting System in tunnel excavation?

A3: While the CO₂ system offers numerous advantages, challenges such as the need for specialized equipment, initial setup costs, and the management of liquid CO₂ supply must be addressed. However, ongoing technological advancements are continuously mitigating these limitations, making CO₂ systems increasingly viable for widespread adoption.

Dialectical Perspective: Balancing Benefits and Challenges

Is the CO₂ Rock Blasting System Technology poised to replace traditional explosives entirely in tunnel excavation?

While CO₂ systems offer substantial safety and environmental benefits, traditional explosives remain prevalent due to their established efficacy and lower initial costs. However, as industries increasingly prioritize sustainable and safer practices, the adoption of CO₂ rock blasting is expected to grow, particularly in regions with stringent safety and environmental regulations. Over time, technological advancements and economies of scale may further enhance the viability of CO₂ systems, potentially leading to broader adoption and eventual replacement of traditional explosives in certain applications.

Can CO₂ Rock Blasting Systems match the energy output of traditional explosives?

Yes, CO₂ systems are designed to provide comparable, if not superior, energy outputs for rock fragmentation. The rapid expansion of liquid CO₂ generates high-pressure shockwaves capable of effectively breaking hard rock formations. Moreover, the controllable nature of these systems allows for precise energy management, ensuring that the blasting process is both efficient and safe.

Future Prospects

The future of tunnel excavation lies in the continued innovation and adoption of alternative blasting technologies like the CO₂ Rock Blasting System. As the mining and construction industries increasingly recognize the importance of safety and environmental stewardship, the demand for such technologies is expected to grow. Investments in research and development will further enhance the efficiency, reliability, and affordability of CO₂ systems, making them even more attractive to a broader range of applications.

Market Adoption:As industries worldwide strive to meet stringent environmental regulations and safety standards, the adoption of CO₂ Rock Blasting Systems is likely to accelerate. Early adopters in countries with robust regulatory frameworks will pave the way for broader global acceptance, setting benchmarks for safety and environmental performance.

Regulatory Support:Governments and regulatory bodies are increasingly supportive of technologies that reduce environmental impact and enhance worker safety. Policies encouraging the adoption of cleaner and safer blasting methods will facilitate the widespread implementation of CO₂ Rock Blasting Systems in tunnel construction and other applications.